[This is an updated version of a post that appears on my old website. – WB3GCK]

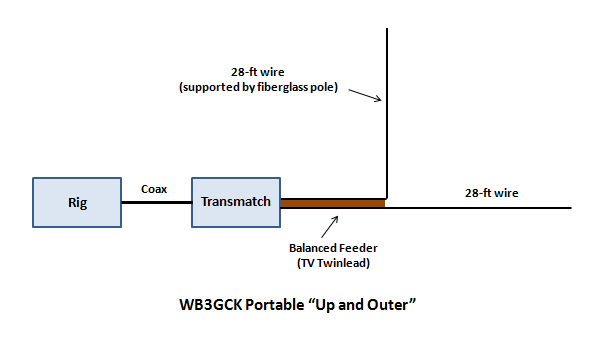

Something about the “Up and Outer” antenna has fascinated me since I first came across it in the 1974 edition of the ARRL Antenna Book. This antenna, which was once popular many years ago, is about as simple as it gets. Simply put, the Up and Outer is a dipole or doublet where one leg is vertical while the other leg is horizontal. Although it seems to be overlooked by Amateurs these days, this antenna offers some significant benefits:

- It’s a good limited space antenna since one leg of the doublet is vertical. It only requires half of the space that a horizontal doublet would take up.

- When fed with balanced line and used with a suitable transmatch, it’s a good multi-band antenna.

- It combines characteristics of both verticals and horizontal wire antennas. That is, it is good for both local and DX work.

- It’s very easy to build and erect.

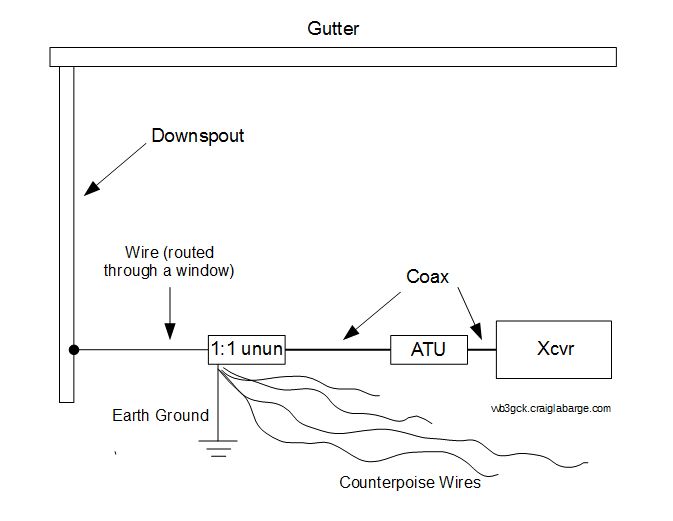

First, a little background on this antenna. According to some handwritten notes from QRP Hall of Famer, C. F. Rockey W9SCH (SK), this antenna goes back to the 20s and 30s. Lew McCoy W1ICP (SK) wrote about it in the October 1960 edition of QST [1]. He didn’t use the name, “Up and Outer;” he merely referred to it as a “limited space antenna.” McCoy recommended horizontal and vertical elements of 30-feet each for operation on 80-10 meters. He also recommended using an open-wire feedline to minimize losses. Information from McCoy’s article has appeared for years in the ARRL Antenna Book. (I first saw it in my 1974 edition [2] and it was still shown in the 1997 edition [3].)

W9SCH wrote a couple of articles about this antenna for SPRAT and appears to have coined the term, “Up and Outer.” In the first SPRAT article [4], Rock suggested using 1/4 wave elements for the lowest band and feeding it with either coax (for single band operation) or balanced line (for multi-band operation). In a follow-up article [5], Rock suggests pruning the horizontal element to equalize the current in the balanced feeder. He noted the imbalance when operating with the horizontal element close to ground. He started with 16-foot elements to cover 30-10 meters.

Another Hall of Famer, L. B. Cebik W4RNL (SK), wrote about a coax-fed version of this antenna for 10 meters [6]. Cebik built his antenna using aluminum tubing and referred to it as the “L Antenna.”

I also exchanged some correspondence years ago with Fred Bonavita K5QLF (SK), another QRP Hall of Famer and fan of the Up and Outer. He told me that W9SCH once mentioned using the copper ball from an old toilet float to top-load the vertical element of the antenna. I later came across a brief write-up by W9SCH on his Copper-Top antenna in the October 1995 edition of QRP Quarterly [7]. Using the toilet ball for top loading, Rock was able to reduce the height of his vertical element by 2-1/2 feet.

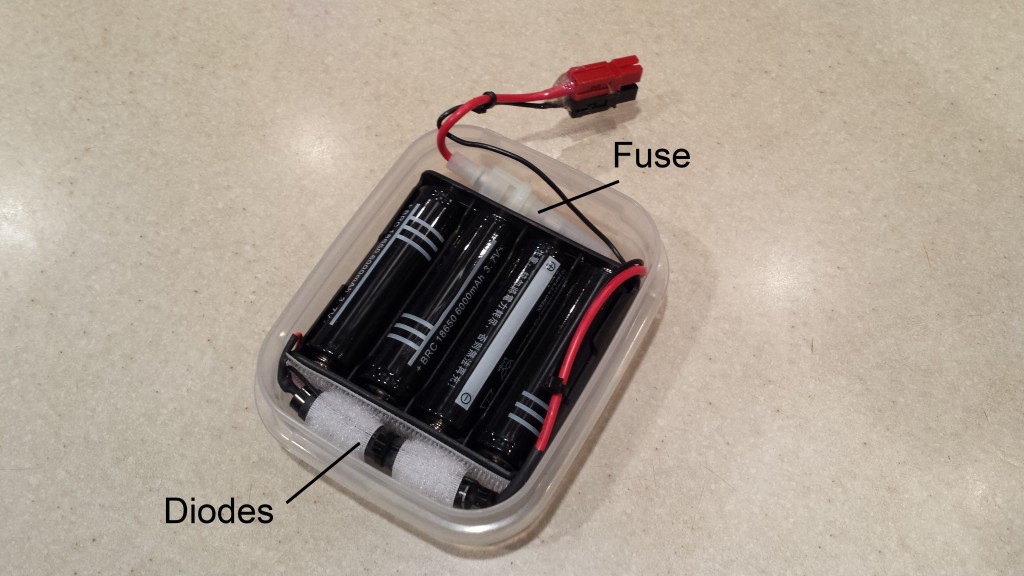

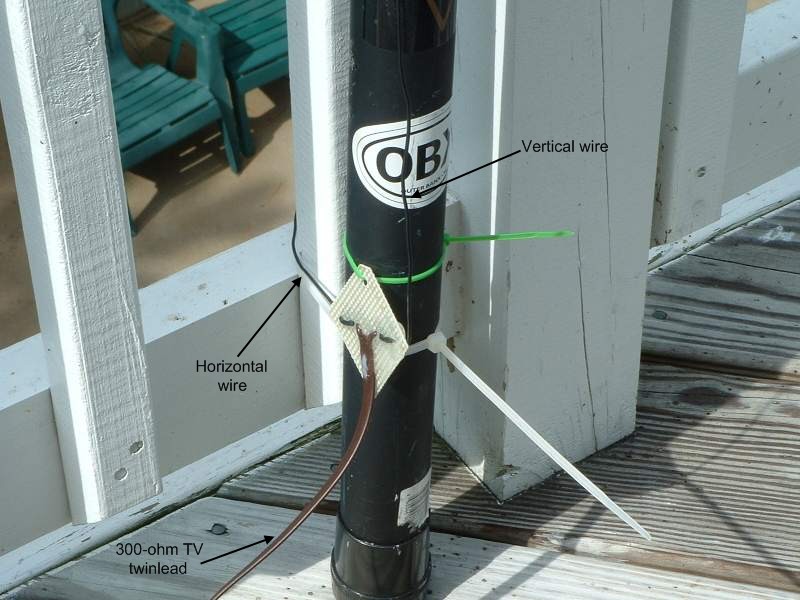

For me, the Up and Outer has turned out to be an ideal portable antenna to use while on vacation in a rented house on the Outer Banks of North Carolina. For several years I’ve used a 56-foot doublet with one wire supported by a 28-foot fiberglass telescopic mast and one 28-foot leg run horizontally. The vertical radiator is typically situated on a 3rd or 4th story wooden deck with the horizontal wire secured to a nearby tree or other support. For feedline, I use 25-feet of TV twinlead (the cheap brown stuff). Using either a homebrew Z-match tuner or an autotuner with a short run of coax to an external 4:1 balun, I’ve been able to use this antenna on 40-10 meters. Your mileage may vary. Depending on the transmatch you use, you might need to adjust the length of the feedline to get a good match on 40 meters.

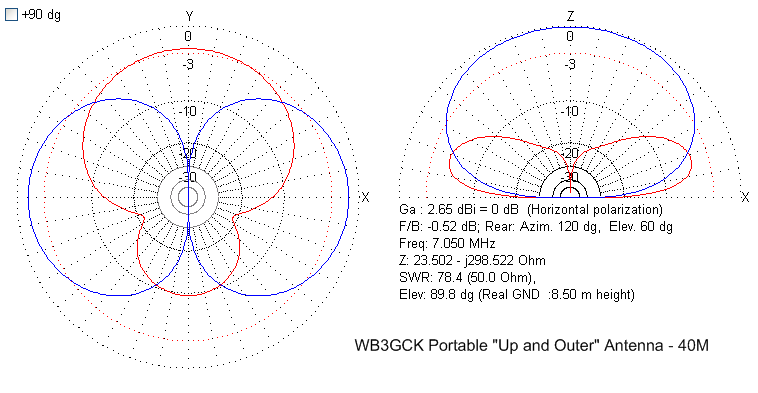

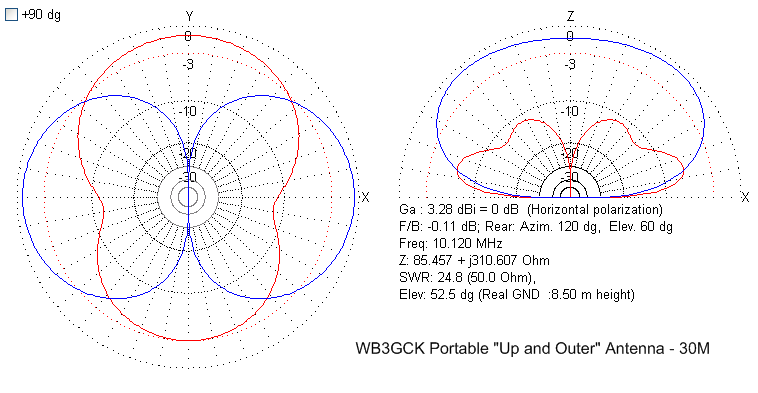

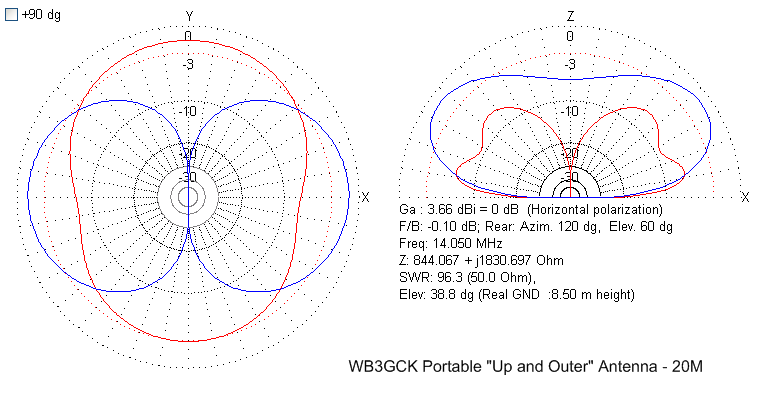

I did some quick modeling of a typical Outer Banks installation using MMANA-GL and you can clearly see the results of the combined horizontal and vertical elements. The horizontal polarity (shown in blue) shows lobes perpendicular to the axis of the horizontal wire, similar to a dipole. The vertical polarity (shown in red) shows a fairly low take-off angle and exhibits some slight directivity on 40 meters in the direction of the horizontal wire. This effect is due to the proximity to ground of the horizontal element and diminishes as you go higher in frequency. So, try to mount the Up and Outer as high above ground as you can.

The modeling bears out my empirical results with the antenna. My version of the Up and Outer has worked very well for both stateside contacts and DX. In particular, it has been very effective for DX contacts on 30 meters. As an added bonus, the 56-foot doublet can also be pressed into service as a normal horizontal antenna in locations where the Up and Outer configuration isn’t possible. So, it’s like getting two antennas in one. Can’t beat that.

If you are looking for a limited-space antenna, give this obscure classic a try!

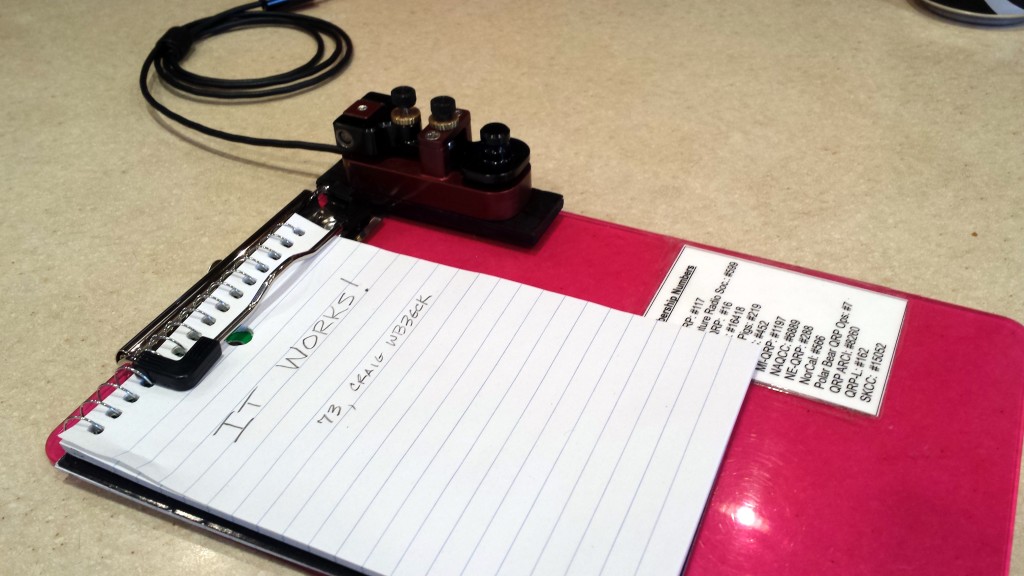

73, Craig WB3GCK

References:

1. McCoy, Lewis G. “A Limited-Space Antenna.” QST October 1960: pp 23-25. (Available in the ARRL online archives)

2. “The ARRL Antenna Book.” 13th Edition, 1974. Newington, CT. pp 187-188.

3. “The ARRL Antenna Book.” 18th Edition, 1997. Newington, CT. pp 7-15, 7-16.

4. Rockey, C. F. “Up and Outer.” SPRAT Issue #67 (Summer 1991): p 18.

5. Rockey, C. F. “A Four Band Up and Outer Antenna.” SPRAT Issue #69 (Winter 1991/1992): p 16.

6. Cebik, L. B. “Whips, Tubes and Wires: Building a 10-Meter L Antenna.” QST December 1999: pp 52-54. (Available in the ARRL online archives)

7. Rockey, C.F. “The Copper-Top Antenna.” QRP Quarterly, October 1995: pp. 40-41.

© 2009-2020 Craig A. LaBarge