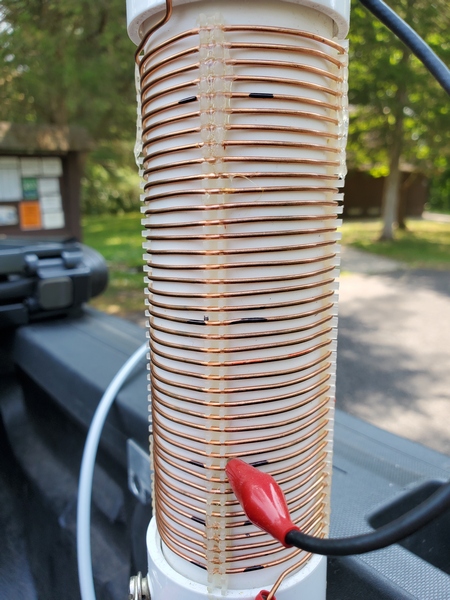

Back in 2017 I built my 19-foot wire vertical, which was my go-to portable antenna for about 4 or 5 years. The concept was simple: It functions as a base-loaded resonant vertical on 40M & 30M and as a random wire on 20M and up. The matching unit contains a tapped toroid for 40M & 30M and is fed through a built-in 1:1 choke. It occurred to me I could do something similar with the 12-foot telescopic whip and homebrew loading coil I’ve been using on my truck of late.

My 12-foot whip setup is resonant on 40M through 17M. You’re probably thinking: “Why not just bypass the loading coil and adjust the length of the whip for 15M through 10M?” Well, being as lazy as I am, that would make band changes a little more involved than I want to deal with. I like having some “frequency agility,” and I’m not above using an ATU to achieve that.

To emulate the scheme I used for the 19-foot vertical, I just needed a choke at the input to my homebrew loading coil. (I could probably go without the choke, but I wanted to keep the coax from becoming part of the antenna.) So, I use the 12-foot whip as a base-loaded resonant vertical on 40M through 17M. For 15M through 10M, I would bypass the coil and use an ATU.

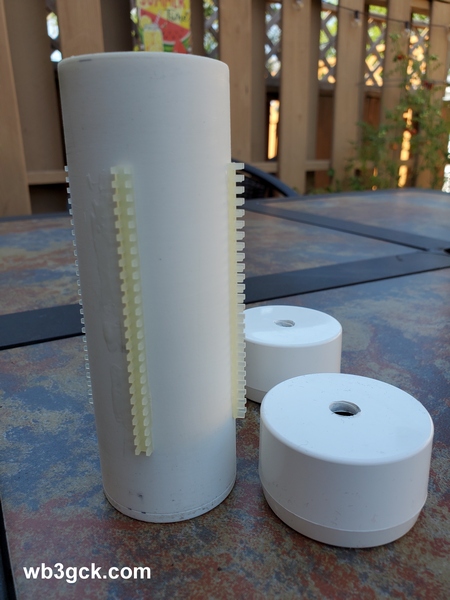

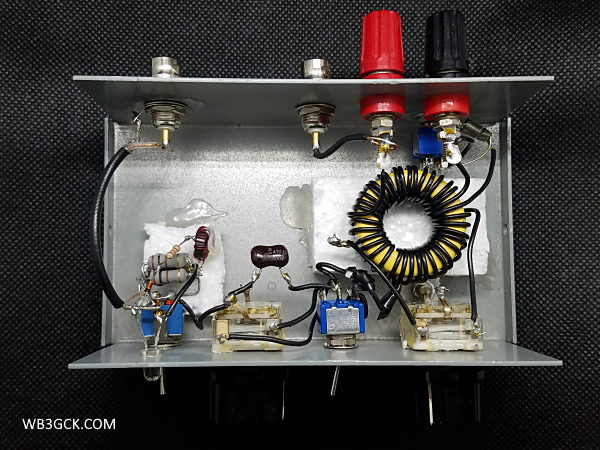

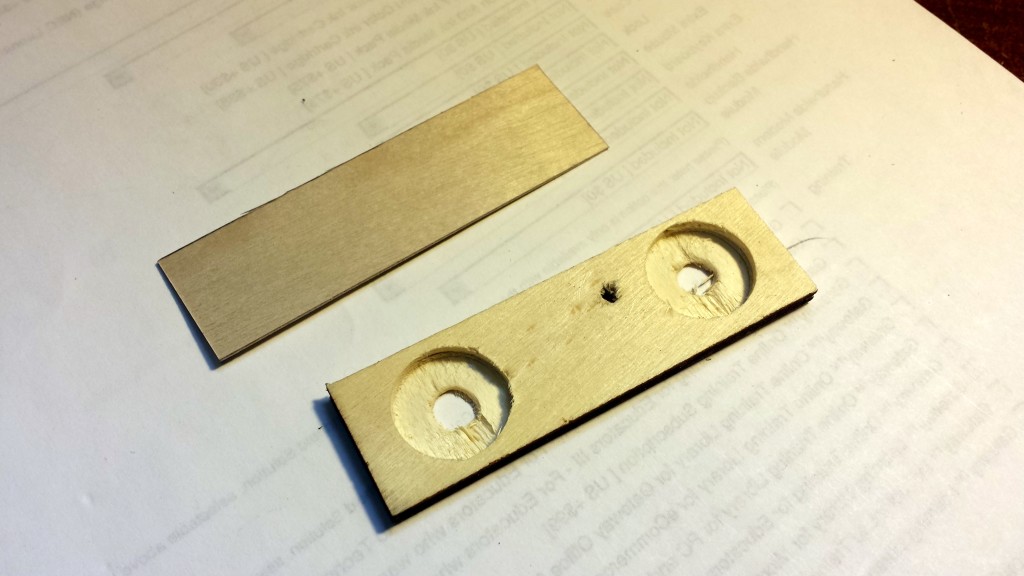

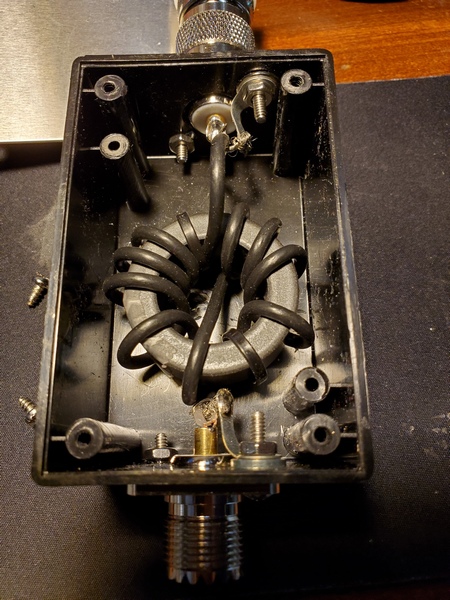

To test this out, I threw together a choke using parts I had on hand. I wound 10 turns of RG-174 on an FT-140-43 toroid. A Radio Shack project box I had in my stash of parts was the perfect size to house the toroid. (I bought it a decade or two ago, and it was still unopened in the original Radio Shack packaging.) Since I installed SO-239 connectors on each end, I had to use an adapter to connect the choke to the SO-239 on the antenna. To hold the coil in place, I wedged a piece of foam packing material between the lid and the core. The completed choke is functional, albeit a little cheesy-looking.

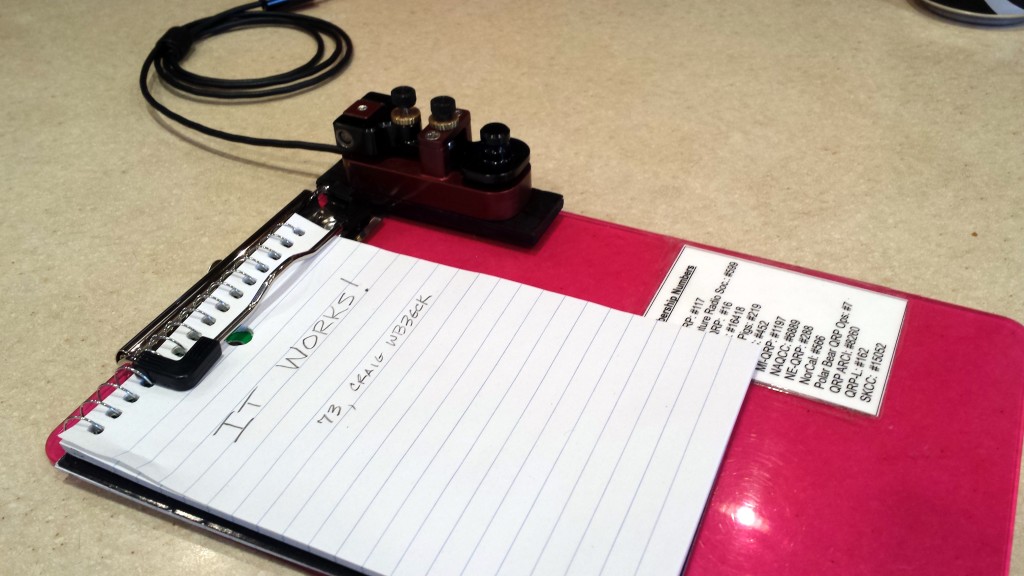

My first test using the 12-ft whip on the higher bands was a success. While activating Ridley Creek State Park (US-1414, KFF-1414), I used my KX3 (5 watts, CW) and installed the choke at the antenna feedpoint. On 40M through 17M, the loading coil functioned as it normally does. On 15M, 12M, and 10M, I bypassed the coil entirely and relied on the KX3’s internal ATU to load up the whip.

The KX3 easily found matches on all three bands, and my results on the air were encouraging. On 15M, I worked stations in Poland, Belgium, France, Ukraine, Germany (3), and the Slovak Republic. I made two stateside contacts on 12M. Up on 10M, I worked some more DX: Germany (2), Italy, and Czech Republic. One of the German contacts was park-to-park.

I’ve used this arrangement on a few more activations since then, including Winter Field Day. My results have been consistently good.

I haven’t done any modeling, but the 12-foot whip seems to be a pretty good length for operating like this. It’s just a little longer than a ¼-wave on 15M and a little shy of ⅜-wave on 10M. On 12M, it’s somewhere between ¼ and ½-wave; so it isn’t resonant on any of the bands of interest.

Although I was pleased with these initial results, I might do a little more tinkering with this setup. I’m toying with repackaging the choke to make it a little more weather resistant. I encountered some rain during the first activation using it. There was no damage to the choke at all, but I always have a tendency to over-engineer things—it keeps me occupied and out of trouble, I suppose.

No scientific breakthrough here. Just a lazy guy “force feeding” a fixed length whip to squeeze a few more bands out of it.

72, Craig WB3GCK