Here’s a quick little hack that might come in handy if your Jackite pole should suddenly collapse in windy conditions. It’s very easy to do and costs nothing, depending on what you have in your junk box.

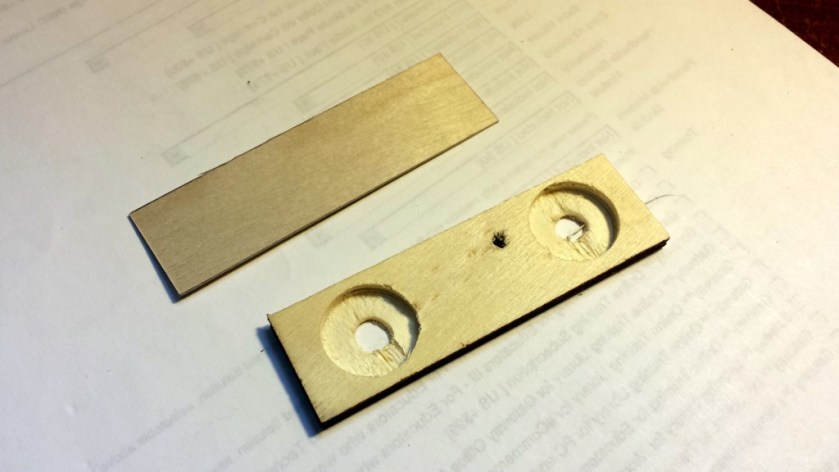

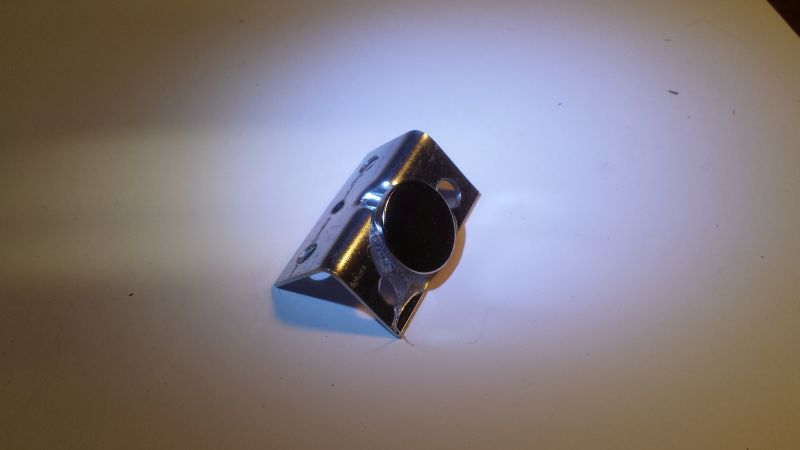

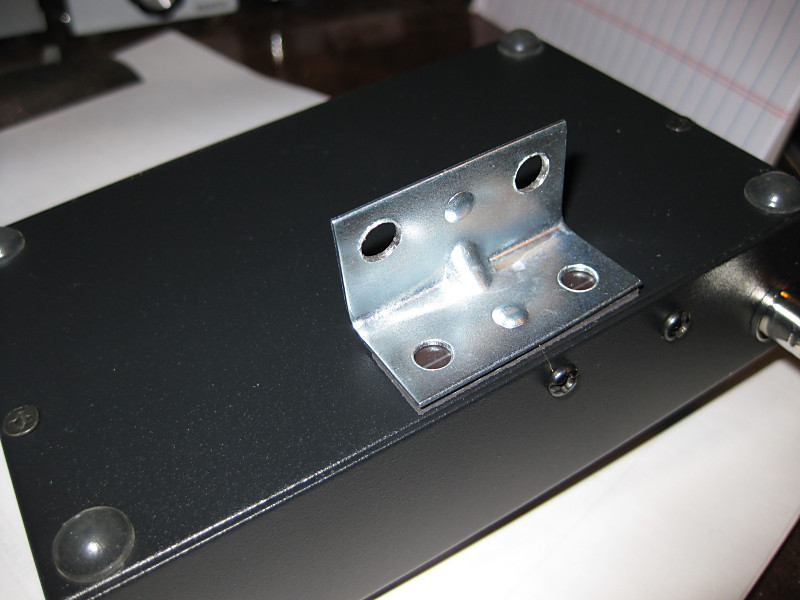

Once in a blue moon, in windy conditions, I have had my 28-foot and 31-foot Jackite poles spontaneously collapse. Usually, when it happens, it’s the second largest tube that collapses into the largest tube. To remedy this, I drilled two 1/8-inch holes in the second largest tube right where it meets the largest tube. I drilled the two holes such that they were directly opposite each other. (See the accompanying pictures if my explanation is confusing.)

To remedy this, I drilled two 1/8-inch holes in the second largest tube right where it meets the largest tube. I drilled the two holes such that they were directly opposite each other. (See the accompanying pictures if my explanation is confusing.)

Here’s how it works. When the pole is fully extended, I just slide a pin through the two holes to prevent the pole from collapsing. For the pin, I used a hook from a bungee cord that I straightened out, using a pair of pliers. The resulting pin is just the right size and it has a nice rubberized coating on it. You could, of course, use something else (a nail, a piece of wire, etc.) for the pin.

Here’s how it works. When the pole is fully extended, I just slide a pin through the two holes to prevent the pole from collapsing. For the pin, I used a hook from a bungee cord that I straightened out, using a pair of pliers. The resulting pin is just the right size and it has a nice rubberized coating on it. You could, of course, use something else (a nail, a piece of wire, etc.) for the pin.

I don’t usually use the pin, except in very windy conditions. I’ll definitely use it during my upcoming trip to the Outer Banks of North Carolina. My Jackite pole will be up for a week and facing some stiff ocean breezes.

73, Craig WB3GCK